If you're looking for a logistics provider, a simple Google search will suggest a wide variety of 3, 4, 5, 6, and even 7PLs – which can be pretty confusing. But we'll share a secret with you: Their services don't differ as drastically as you might imagine.

One piece of evidence proving this statement is that all the top 4 (5/6/7) PL providers are the leading 3PLs – who leverage their industry expertise and resources to expand their services and offer higher-level consulting/managerial assistance and tech support to their clients.

But let's start from the beginning and explore what 4PL companies are, how they differ from other logistics providers, and when it’s worth considering their services.

What is fourth-party logistics (4PL)?

A fourth-party logistics (4PL) provider (sometimes also referred to as a lead logistics provider or LLP) is a specialized company that strategically oversees and manages supply chains for other businesses. It leverages its expertise and technologies to optimize logistics operations, increase efficiency, and reduce costs through the coordination of all supply chain activities.

Simply speaking, a 4PL is an expert team that businesses hire to make their supply chains work better and cheaper so that the companies themselves can focus on their core operations. The role of a 4PL is to ensure that your entire supply chain operates seamlessly, from procurement of materials to last-mile delivery and from planning to performance monitoring.

The term 4PL was coined in 1996 by Accenture (at that time Andersen Consulting). Originally, it was defined as “A supply chain integrator that assembles and manages the resources, capabilities, and technology of its own organization with those of complementary service providers to deliver a comprehensive supply chain solution.”

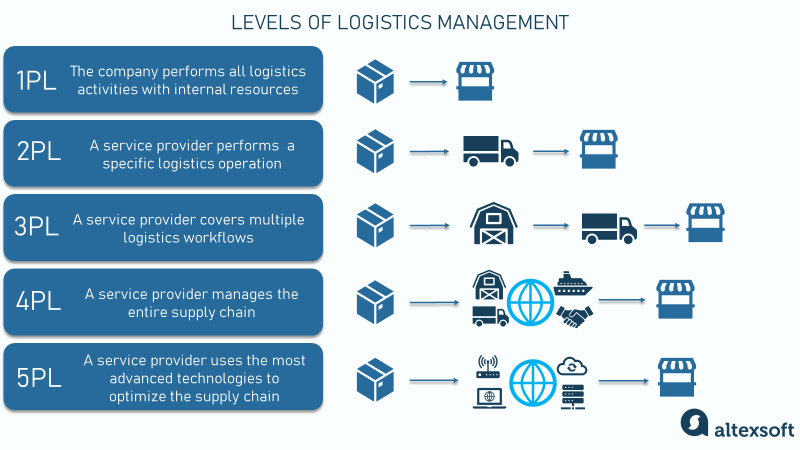

The 4PL role was defined as a new type of player in the logistics world distinct from the others. To get a bigger picture, let’s take a step back and look at all the levels of logistics management.

Logistics levels from 1PL to 5PL

There are 5 levels of managing logistics operations. Each level represents the number of parties involved, where 1PL implies a shipper being the key player who manages all the logistics, 2PL includes the shipper and the carrier, and so on. So each stage adds to the complexity of services offered, with the higher levels providing more strategic and integrated management of the supply chain.

1PL (First-Party Logistics). This is the most basic form of logistics, where a company or individual manages the transportation of goods on their own. Businesses that operate their own trucks and warehouses to move and store their products are considered 1PL providers.

Example: A farmer grows vegetables and sells them to the grocery store.

2PL (Second-Party Logistics). At this level, companies start outsourcing specific logistics functions (usually transportation) to external service providers such as couriers, trucking companies, cargo air carriers, etc.

Example: A farmer hires a truck carrier to transport vegetables to the store.

3PL (Third-Party Logistics). 3PL providers offer a broader range of logistics services that go beyond just transportation. They can handle storage, packing, freight forwarding, distribution management, order fulfillment, etc.

Example: A farmer hires a 3PL to store vegetables in its warehouse, as well as to pack and ship them to multiple grocery stores.

4PL (Fourth-Party Logistics). 4PL providers are the next level up, offering a more comprehensive management role in the supply chain. They don't own the logistics assets but instead integrate and manage all logistics services, including those offered by 3PLs.

Example: A 4PL manages a network of 3PLs on behalf of the farmer to take vegetables to grocery stores.

5PL (Fifth-Party Logistics). This is the recent concept of the most advanced logistics level, where providers develop and implement advanced supply chain solutions, particularly in eCommerce and digital marketplaces. 5PL providers aim to optimize logistics operations in a global arena, mainly through the use of big data, artificial intelligence, and other advanced technologies to achieve efficiencies and cost savings at scale.

Example: A 5PL manages the entire supply chain on behalf of the farmer and implements AI/ML technologies to scrutinize every stage and find optimization opportunities.

Please note that the lines between the last three types are often blurry. From our experience, the terms that are most often confused are 3PLs and 4PLs, so let’s pay them a little more attention.

3PL vs 4PL

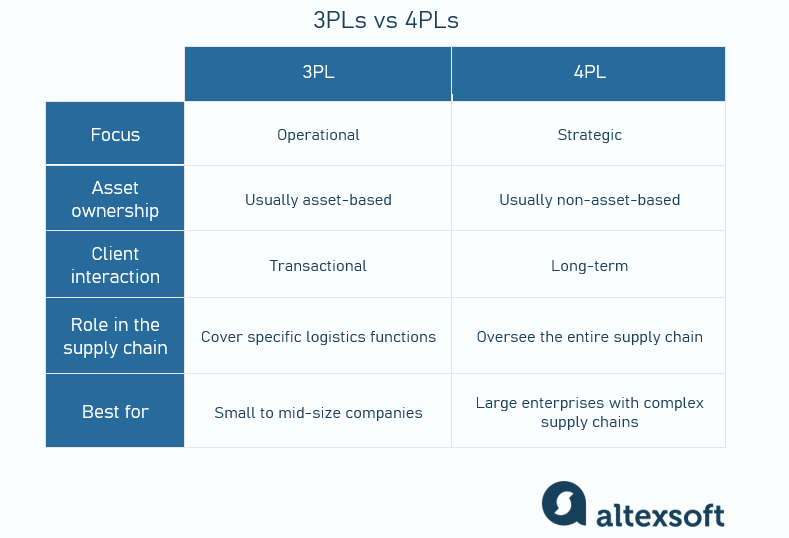

The key difference between 3PLs and 4PLs lies in the scope of their services and the level of management and integration they offer.

Focus. 3PLs have a more operational focus, covering specific logistics workflows like warehousing or transportation and sometimes offering other value-added services like packaging, kitting, and inventory management.

In contrast, 4PLs have a higher-level role, managing and coordinating the entire supply chain. Their services go beyond operational tasks to include strategic supply chain planning, optimization, and the integration of technology solutions.

Asset ownership. Many 3PLs own or lease the physical assets required for their services, such as vehicles or distribution centers. Conversely, most 4PLs do not own logistics assets themselves. Instead, they work with 3PLs and other service suppliers, organizing their activities and presenting a single point of contact for their clients.

Client interaction. 3PLs work directly under the client's guidance, executing specific logistics tasks and operations that have been outsourced to them. Interactions with 3PLs are often transactional, covering certain lanes or shipment batches.

Meanwhile, 4PLs work with their clients at a strategic level with a long-term perspective, often embedding their staff within the client's organization to thoroughly understand and improve the entire supply chain.

Role in the supply chain. 3PLs act as a contractor that takes over particular logistics functions. They are responsible for managing inventory and shipping goods, usually not engaging in strategic planning or integration of the entire supply chain.

4PLs, however, play a managerial and integrative role, overseeing not just the physical logistics but also the data, technology, and overall supply chain strategy. They aim to provide a seamless, optimized supply chain solution aligned with the client’s business goals.

In summary, while 3PLs are more about executing specific logistics operations, 4PLs offer a higher level of management, focusing on the integration and optimization of the entire supply chain.

Now that we’ve cleared up all the terms, let’s look at the services 4PLs offer in more detail.

Core services and functions of 4PL companies

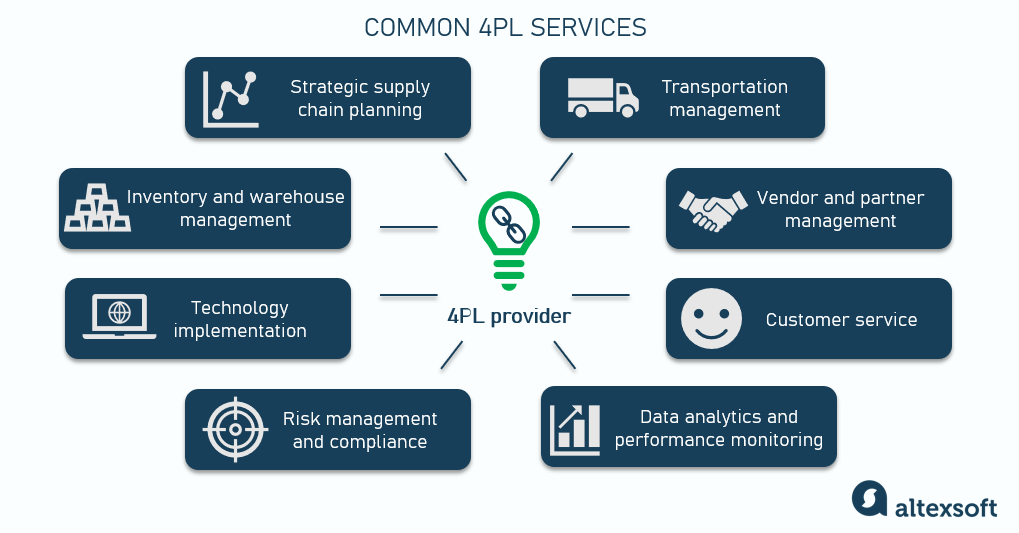

Here’s a scope of services you can expect when partnering with a 4PL provider.

Strategic supply chain planning

To design an optimal supply chain strategy tailored to your business needs and industry specifics (or enhance an existing one), a 4PL will assess your current logistics operations and suggest ways to improve them. In addition, a 4PL might also analyze market trends to forecast customer demand and help you plan for capacity needs and inventory levels.

Transportation management

4PLs negotiate contracts and select carriers for cost-effective, reliable, and trackable transportation. They often work at a global scale and coordinate the international movement of goods across different modes of transport.

Vendor and partner management

4PLs help you manage relationships with suppliers to ensure quality, reliability, and adherence to contracts. They also select and coordinate all the logistics partners, such as carriers, 3PLs, and freight forwarders to ensure they meet performance and service level agreements.

Inventory and warehouse management

Another responsibility of 4PLs is inventory optimization. They develop and implement strategies to maintain optimal inventory levels, reducing carrying costs while ensuring product availability. They also arrange and oversee warehouse operations, improving handling practices to maximize space and efficiency.

As a real-world example, look at the case study of Incora developing a program to optimize inventory management for a power systems manufacturer (among other processes). The created strategy included such activities as inventory forecasting, implementing just-in-time delivery, quality control, supplier engagement, etc.

Customer service

A 4PL closely manages the relationships of your business with customers, ensuring that their needs are met, including order fulfillment accuracy, timely delivery, and responsive service. In addition, a 4PL takes care of returns, setting up efficient reverse logistics operations.

Risk management and compliance

Supply chains are very prone to various risks and disruptions, so there’s always an immense need for effective risk assessment and mitigation strategies. A 4PL continuously monitors your internal supply chain activities as well as external market conditions to identify potential risks and develop strategies to avoid them or reduce their consequences.

Also, when operating in global markets, you have to ensure that all supply chain activities comply with local, national, and international regulations. 4PL expertise allows them to see to it.

Technology implementation

Another part of a 4PL’s service list is building a technological infrastructure. If you already have your own software tools, the 4PL provider will help you integrate them into a single, comprehensive IT system to enable seamless data exchange.

If some of your logistics operations lack tech support, a 4PL can help you implement and get the most out of various solutions such as

- transportation management systems (TMS),

- warehouse management systems (WMS),

- business intelligence platforms, and so on.

Please note, however, that while 4PLs work closely with all these software tools, a heavy reliance on IoT, AI/ML, and big data solutions for maximum optimization is a distinctive feature of 5PL providers. Such well-known consulting companies as Deloitte, Accenture, and Capgemini can be called 5PLs as they help businesses build highly technological, AI-powered supply chains.

Data analytics and performance monitoring

With all the tools in place, a 4PL acts as a control tower, coordinating various operations and getting insights into supply chain performance to make informed decisions.

To identify bottlenecks, inefficiencies, or negative trends, 4PLs monitor multiple performance metrics throughout all stages of the supply chain. Such comprehensive monitoring is possible due to collecting data from internal systems aa well as external information from partners and data providers.

Conducting advanced data analytics helps 4PLs find unobvious patterns and understand the reasons behind existing issues. Once they know what has to be changed, 4PLs run what-if scenarios to understand how exactly they can optimize operations.

For illustration, check out a case study of Maersk providing 4PL services to Aramco, a leading global petroleum and natural gas company based in Saudi Arabia. Throughout their cooperation, Maersk developed and implemented ad hoc Supply Chain Intelligent Dashboards to enhance visibility and monitor performance. They also targeted other processes such as booking management, freight audit, warehousing, carrier management, and so on.

Read more about supply chain analytics in our dedicated post.

Other services 4PLs can provide are quality management, claims handling, sustainability initiatives support, and so on.

When to use 4PL logistics and why to use it

Here are key scenarios and reasons why you, as a company owner, might choose to partner with a 4PL.

Comprehensive supply chain optimization and cost reduction

If you're looking for a single point of control over your entire supply chain, a 4PL can provide this by managing all aspects of logistics from suppliers to end customers. Having an extensive partner network, 4PLs can often achieve economies of scale and reduce transportation, warehousing, and overall logistics costs.

Here’s a research paper that analyzed whether switching from a 3PL to a 4PL model proved cost-beneficial to a South African non-food retailer. The study demonstrates that the 4PL model was able to achieve ongoing savings over a 10-year contract period, in particular, by cutting transportation costs due to freight consolidation and negotiating group rates from carriers.

Plus, with a 4PL's focus on strategic planning and efficiency, you can expect improvements in delivery times, customer service, and overall supply chain reliability. And if you aim to leverage modern technologies for supply chain optimization, 4PLs provide the necessary expertise and tools to implement these solutions effectively.

Scaling your business

As you expand globally, managing logistics across different regions can become complex. A 4PL offers the expertise and network to manage international logistics, customs, and compliance efficiently.

Another case scenario is diversifying or increasing product offerings, which complicates your supply chain. A 4PL can integrate and manage this additional hassle, ensuring smooth operations.

Focusing on core competencies

A 4PL partnership gives you access to logistics and supply chain professionals without the need to develop this expertise in-house or build a logistics network yourself. It will allow you to allocate more resources to your core business activities, such as product development, marketing, and sales, while the 4PL handles the complexity of logistics.

Summing up, turning to a 4PL provider is beneficial when you're looking for a strategic partner to manage the complexities of your supply chain comprehensively, allowing you to focus on growing your business, improving efficiency, and meeting strategic objectives. The benefits of such a partnership are apparent:

- cost savings through optimized logistics operations,

- improved supply chain visibility and scalability,

- enhanced risk management that supports greater resilience and flexibility in response to market changes, and

- access to expertise and advanced technologies.

However, these gains often come at a hefty price as 4PL’s services aren’t cheap. Besides, outsourcing operations always results in less control over your workflows. So to make the best decision that aligns with your business goals, you must first carefully consider all the pros and cons of partnering with a 4PL – and explore the market to compare existing options.

Top 4PL companies

The 4PL market has been steadily growing over the last decades. A 4PL Logistics Market Report states that in 2021, the global 4PL market was valued at $49.84 billion, and in 2030, it’s expected to reach $89.95 billion with a CAGR of over 7 percent. It also forecasts that while there were approximately 10,000 companies using the services of 4PL providers, by 2030, this number is expected to increase up to 20,000.

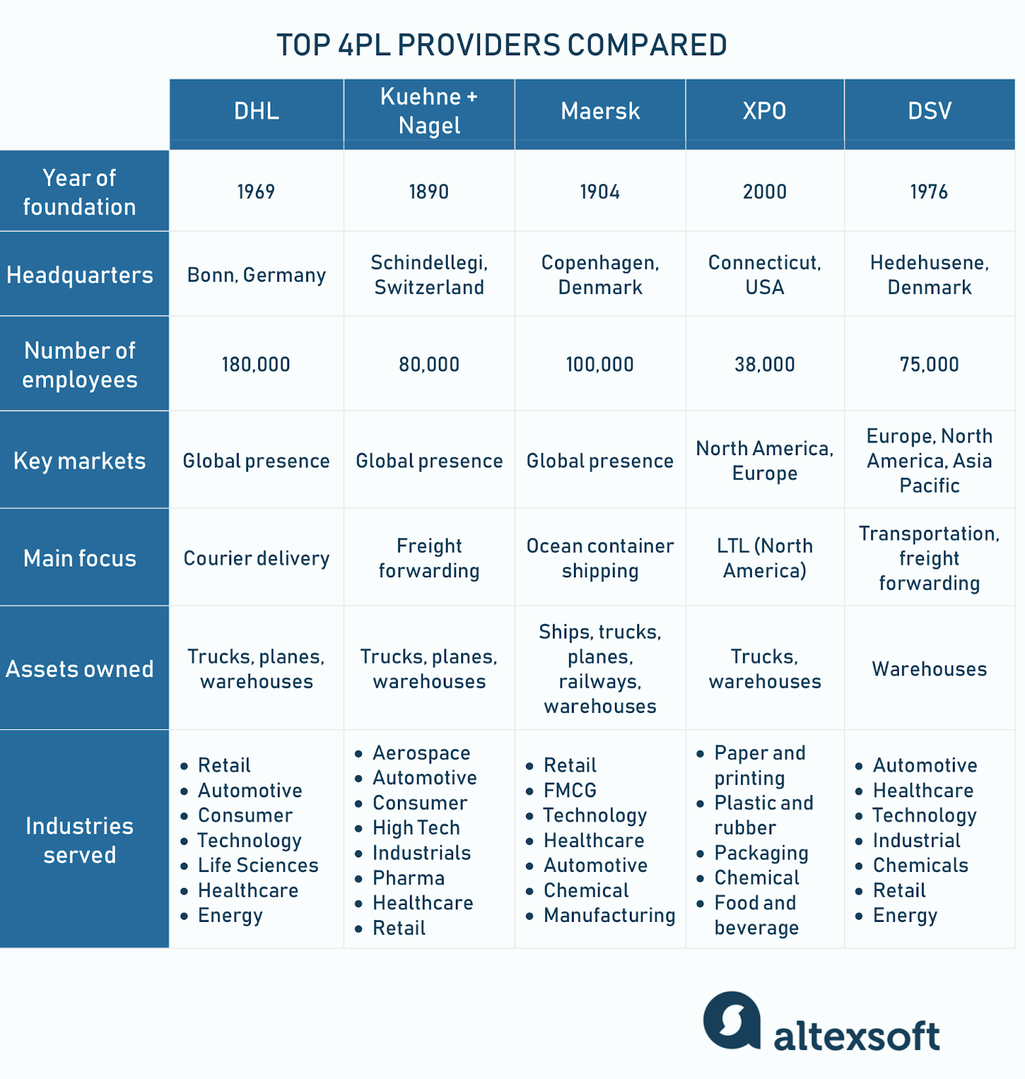

There are several companies recognized as leading providers in the 4PL space, known for their comprehensive solutions, global reach, and innovative approaches to logistics and supply chain management. Don't be surprised to see well-known courier and 3PL companies on the list – who if not them should be there, with their extensive industry expertise and a broad range of offerings for different business needs.

Please note that we don’t aim to promote any of the companies listed below but only to provide you with information for further research.

DHL Lead Logistics Partner. DHL is a Germany-based logistics provider known for its strong global presence (220 countries and territories) and use of innovative technology. DHL provides 4PL services integrating customized supply chain solutions and leveraging its global network for logistics optimization. As a 4PL, it offers

- Design services to optimize logistics workflows;

- Management services to handle outsourced supply chain operations, including coordinating suppliers and logistics providers, freight forwarding, customs, etc.;

- Operations to maximize visibility with its Control Tower solutions; and

- Continuous improvement to minimize costs with their analytics-based “Total Logistics Cost Management” product.

Kuehne + Nagel. Founded in Germany in 1890, Kuehne + Nagel has evolved into a global logistics partner operating 1,300 locations in 100 countries. Having such an extensive network and 130+ years of industry experience – complemented by their digital initiatives – the company offers comprehensive supply chain management with the main focus on visibility, resilience, and sustainability. Their Software-AND-a-Service offering “integrates more than 40 technology partners into one intuitive platform and enables collaboration with all supply chain stakeholders.”

Maersk 4PL Logistics Services. Founded in 1904, Danish-based Maersk is a recognized leader in global container shipping that owns over 70 container terminals worldwide and has a fleet of 786 ships. It combines its logistics expertise and its vast shipping network with digital solutions to provide end-to-end supply chain management.

To enable complete visibility and connectivity, Maersk offers a proprietary control tower platform Maersk NeoNav™ – with a promise to reduce transportation costs, improve perfect order fulfillment rate, increase revenue, and so on.

XPO Logistics Key-PL. While XPO is known as one of the leading providers of less-than-truckload (LTL) shipping in North America, its European division offers a wider range of services, including those of a 4PL. They leverage proprietary tech solutions to cover the entire supply chain and to assist their clients, there’s a team of 200+ experts in transportation, data science, and software development and implementation. XPO also boasts a network of over 1,400 carriers to help companies choose the best shipping options for their freight.

DSV Lead Logistics. Another recognized logistics expert, DSV is a Dutch company now present in 80 countries. With over 40 years of industry experience, DSV offers complete supply chain management with a key focus on flexibility and cost reduction (which are possible, among other factors, due to the company’s asset-light business model). Their optimization services cover all operational workflows from strategy definition to performance management.

Some other industry-recognized 4PL providers worth considering are UPS Logistics Solutions, FedEx Logistics, TMC (a division of C.H. Robinson), etc.

If you're looking for a 4PL partner, consider starting your research with these expert companies to get a better vision of their offerings, industries served, and how they align with your company's needs. You’ll have to contact their representatives to get more information about their services and prices since they’ll depend on your specific situation and requirements.

To wrap up, let’s look at what your cooperation with a 4PL company will most likely look like – in case you decide to partner with one.

4PL implementation process

So once you’ve decided on the optimal candidate to assist you with supply chain management, contacted them, and negotiated cooperation terms, here’s what will happen next.

Assessment

First thing first, a 4PL will analyze the current state of affairs to understand your existing operations, challenges, and goals. They will also identify areas where efficiency, cost savings, or improved performance can be achieved.

Tip: Appoint a project manager or a project management team that includes members from both your company and the 4PL provider. Also, as you provide information for the assessment, ensure data security and compliance.

Strategy development

Based on the assessment results, the 4PL will develop a customized roadmap that contains key objectives, optimization initiatives, milestones, and KPIs.

Tip: At this stage, work closely with your partner to develop a detailed plan that outlines not only the project scope but also the resource requirements. This way, you’ll have a complete picture and will be able to better evaluate the cost of this transformation project.

Design

Once all the key stakeholders approve the strategy, the 4PL will develop the design of your logistics network – or redesign the existing one. It will include

- physical objects such as warehouses or distribution centers,

- partnerships with suppliers and logistics providers,

- operational workflows and processes, and

- technology solutions.

Tip: As you design your new network and processes, establish clear communication protocols detailing how and when information will be shared between your team and the 4PL. This includes routine updates, escalation procedures for issues, and strategic reviews.

Implementation

Together with the 4PL, you’ll start to gradually implement the agreed-upon changes, like onboarding selected vendors and partners, implementing and integrating software, and adjusting workflows. The degree of your involvement will depend on the level of control you decide to outsource to your partner.

Tip: Before going fully live, conduct pilot testing of the integrated systems and processes in a controlled environment so that you can identify and resolve any issues before they impact the broader operation. Also, consider a phased roll-out of the partnership to manage risks effectively. Start with less critical operations or regions and gradually expand to other areas as confidence in the system grows.

It’s also important to ensure that teams are fully supported. This includes having IT support readily available to address any technical issues and management support to make quick decisions if needed.

Performance monitoring

Closely monitor the supply chain performance and gather feedback from stakeholders to track progress toward your objectives and identify areas for further improvement. Regularly review your strategy and be ready to adapt to changing market conditions, customer demands, tech innovations, or other factors.

Tip: Establish a consistent feedback loop where you and the 4PL regularly review performance data, discuss challenges, and identify opportunities to optimize operations further.

The process of partnering with a 4PL is iterative and requires ongoing communication and collaboration to ensure that the partnership remains aligned with your strategic goals and delivers continuous value to your supply chain operations.

By focusing on careful planning, technology integration, process alignment, and robust communication, you’ll smoothly transform your operations to 4PL management, minimizing disruptions and setting the stage for long-term success in supply chain optimization.

Maria is a curious researcher, passionate about discovering how technologies change the world. She started her career in logistics but has dedicated the last five years to exploring travel tech, large travel businesses, and product management best practices.

Want to write an article for our blog? Read our requirements and guidelines to become a contributor.