Every business deals with inventory one way or another. However, if you run, say, a real state office, a law firm, or a daycare center, you probably don't have a problem counting your office supplies, light bulbs, or furniture and don’t need a sophisticated inventory management solution to maintain records and support the reordering process.

On the other hand, if your company is part of the supply chain, whether you deal with manufacturing, manage a warehouse, or run a retail store, you’re probably familiar with such problems as time-consuming inventory counts, running out of stock because of late reordering, or shortages due to inaccurate demand planning. In this case, it becomes obvious that efficient inventory management is crucial for the smooth operating and overall success of your business.

In this article, we’ll talk about the common challenges related to managing inventory and the ways technology can help address them and optimize associated processes.

What is inventory management?

Inventory management is a set of activities aimed at tracking stock and maintaining optimal stock amounts. It encompasses control over the entire flow of goods, from purchase to sale, with the purpose of having the right amount of the right stock at the right place at the right time.

Note that inventory management is different from inventory control, even though these two notions sound alike and are often used interchangeably. Inventory control handles stock that you already have in your warehouse or storage facility while inventory management is a broader term that includes activities of strategic planning, forecasting demand, and replenishing stock amounts.

Inventory management is important for different participants of the supply chain including

- manufacturers,

- warehouses,

- wholesalers,

- retailers, and

- eCommerce businesses.

All these organizations deal with ordering supplies, storing goods, and fulfilling customer orders, so they have to carefully track their inventory. However, the types of inventory they handle can vary. Let’s go over the main ones.

Main types of inventory

There are many different types of inventory, but typically they are grouped into 4 categories.

- Raw materials (including components) are any items that are needed to produce finished products. For example, if you manufacture clothes, then fabric, threads, and sewing accessories would be the raw materials that you purchase and use in the production process.

- Work-in-progress (WIP) inventory includes items that are partly finished and not ready for sale yet. In clothing manufacturing, shirts that are finished except for the buttons being sewn on would be considered WIP.

- Maintenance, repair, and operations (MRO) goods are items that support the manufacturing process and are not a part of the finished product. Continuing the garment industry example, it can be needles, patterns, scissors, and so on.

- Finished goods are products that are manufactured and ready to be sold.

With the existing types of inventory in mind, let's define the main stages of the inventory management process.

Stages of inventory management

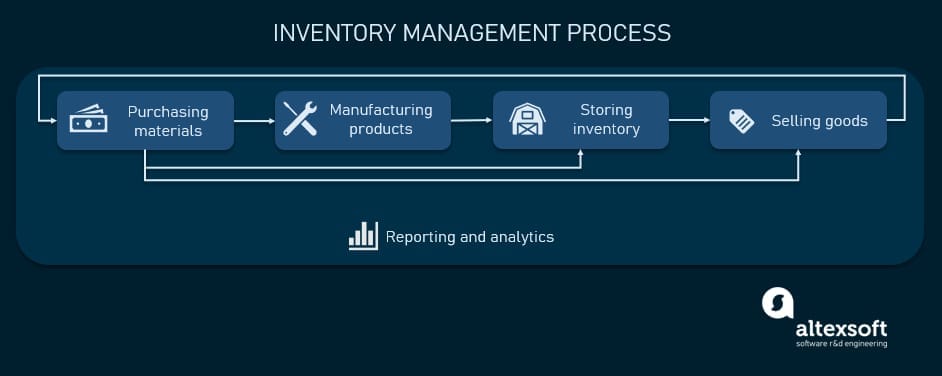

As we said, inventory management involves tracking of goods through manufacturing, storing, and sales. So, we can break this process into five stages.

- Purchasing (reordering) is buying raw materials needed for manufacturing or finished goods that are intended to be sold.

- Production is the process of turning raw materials into finished goods or preparing items for sale.

- Storage is holding stock, e.g., raw materials before they are used or finished goods before they are sold.

- Sales is transferring goods to the customers.

- Reporting is monitoring how much a business is selling and how much profit it makes.

Main stages of inventory management

Obviously, not every company goes through all the stages. For example, wholesalers would most probably skip production altogether. That said, these stages go in a cycle and at each stage you need to know exactly what items you have in store (in production/on the shelves), where they are, as well as when and how much to order to ensure smooth and uninterrupted business operations.

That brings us to the next question: What are the most common problems and difficulties associated with inventory management?

Inventory management challenges

Managing inventory is a complex process involving many aspects. So, handling it manually or with the help of disconnected legacy systems easily causes errors and financial losses. Here are some of the main pitfalls.

Main inventory management problems

Erroneous inventory planning. Calculating the right amount of stock for multiple product types is a challenging task, whether it concerns ordering raw materials necessary for manufacturing or predicting the ever-changing customer demand for retail sales. If done wrong, it can lead to one of the two equally frustrating problems.

- Overstocking is having too many goods. Ordering and keeping extra goods “just in case” is a bad idea because you have to pay for additional storage space, you have your invested cash tied up, and besides, you risk being left with unsold items that you’ll have to discard (for example, perishable or seasonal products).

- Out-of-stocks means not having enough goods. In this case, either the production process stops causing delays and possible non-fulfillments, or you lose revenue and have unhappy customers that want to buy the product that you ran out of. In 2020, the value of stockouts in the retail sector was estimated as $1.14 trillion -- that sounds like a problem, doesn’t it?

The COVID-19 pandemic proved that sometimes demand is completely unpredictable and shortages are inevitable, source: Shutterstock/Zorro Stock Images

Disparate data. The disconnected structure of different systems in the supply chain can be a cause of mistakes and uninformed decisions. It can also happen in case you have multiple warehouses, points of sale, manufacturing facilities, etc. Lousy data sharing leads to poor planning and lack of understanding of what’s going on with your business.

Wrong purchase time or amount. The Future of Supply Chain report by BCI states that in 2020, 73 percent of their respondents encountered a detrimental effect on the supply side. The process of replenishment involves accurate prediction of the amount of items you need and also calculating the time needed for them to be delivered as lead times vary across different vendors. Any supply disruptions can result in the problems we described above.

Inaccurate inventory counts. Inventory count is a process of monitoring what you have in store to ensure there are no discrepancies. Many businesses still perform their inventory counts manually, which takes too much time and is prone to errors. Such a lack of visibility can result in either lost items or overselling (that’s when you sell something you actually don’t have, oops).

Disorganized warehouse. A lack of order in a warehouse is, unfortunately, a very frequent problem. Unoptimized inventory allocation, poorly labeled areas, incorrect storage conditions -- all this leads to wasted time, lost or damaged goods, and possible theft.

There’s no way you can find what you need in a messy storage (photo by i ♥ happy!!, Flickr, under CC by 2.0 license)

Some other common problems include inaccurate record-keeping, errors in reporting, lack of visibility into the entire picture of your business processes, etc.

All these inefficiencies can be optimized with the help of the right technology. Let’s see what can be done.

Inventory management software

An inventory management system (IMS) is software for tracking inventory, controlling stock levels, handling orders, sales, returns, reports, and more. It helps automate the previously manual processes and increases efficiency, accuracy, and speed of operations.

There are two main types of IMSs:

- perpetual system that manages inventory in real-time, and

- periodic system that conducts occasional counts of stock and provides periodic updates.

Well, the pros and cons are obvious. Periodic systems are cheaper, simpler, and offer more limited capabilities, while perpetual ones require more investments and are more advanced, providing real-time visibility and control. However, different businesses require different solutions and approaches so the choice depends on your specific needs.

An IMS can be a standalone solution or you can have similar functionality in your warehouse management system (WMS), supply chain management platform, enterprise resource planning (ERP), or other business management platforms.

Key features to look for in inventory management software

Obviously, there’s a wide variety of available solutions on the market, starting with simple mobile apps for basic operations like stock counts and going up to full-fledged, custom-developed enterprise platforms fully integrated with other business applications. Here, we’ll go over the main features of IMSs to help you decide what functionality you might need to meet your unique business requirements.

Inventory control and replenishment

As we mentioned earlier, inventory control lies at the heart of inventory management with tracking and reordering being the most important processes.

Tracking inventory automatically is a huge time saver. The IMS keeps records of the exact number of units of all the items you have on hand as well as their location and status (on order, in transit, in stock, etc.). Inventory levels are automatically updated in real time as purchased or returned items arrive and sales through various channels occur (though it doesn’t mean you have to abandon your stock counting activities to match physical stock with your records and avoid discrepancies).

With real-time data sharing, you gain visibility into your inventory, save time locating needed items, and avoid disruptions, theft, and overselling.

Some useful features that also support tracking and help streamline the picking workflow are image attachment and barcode/RFID scanning capabilities. They help increase accuracy and reduce the common problem of mispicks.

Mark Parker, President and CEO of Nike, admits the benefits of RFID technology: “We placed RFID in nearly all NIKE footwear and apparel, which is hundreds of millions of products. RFID gives us the most complete view of our inventory that we have ever had. It's quickly becoming the most precise tool in our arsenal to meet an individual consumer specific need at the exact right moment.”

Stock counts and cycle counts are still essential procedures in any supply chain facility. If done with barcode and RFID scanners that automatically update inventory levels in the system, these processes take less time and accuracy is improved. You just need to confirm the data you already have instead of manually counting items and filling in spreadsheets.

Optimizing layouts is especially important for big warehouses. With the help of software, you can create various designs and simulations that allow you to estimate the layout, determine and optimize the required staff and equipment quantities, analyze freight traffic flows, and much more. Check the video below as an example of such capabilities.

CLASS warehouse design tool

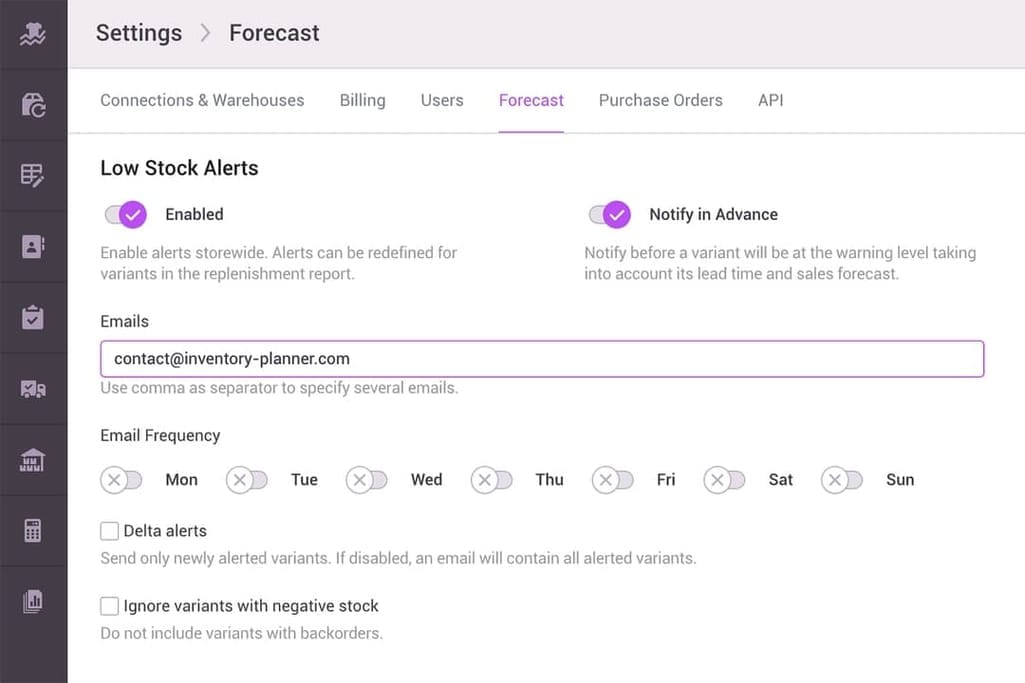

Automating reordering is probably the most valued and stress-relieving feature for many supply managers. The IMS can be programmed to detect low stock levels and automatically create and send purchase orders for the needed items (including items sold in packages or kits). You can also set customized alerts to inform you when you reach the reorder point as you are running low on some products.

Setting low stock alerts in the Inventory Planner

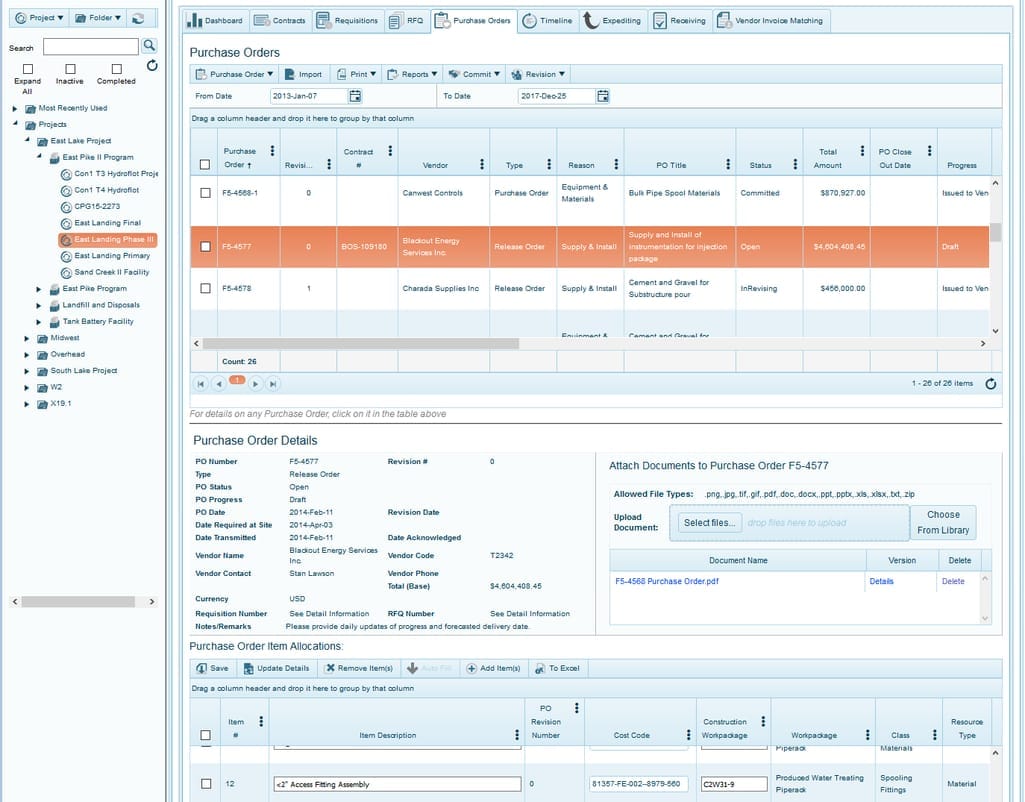

Purchase order management makes creating and tracking purchase orders easier and faster. Manual entry is minimized as all the supplier details are extracted from the database, items are added by simply scanning the barcode, other documents are easily attached, and the order is emailed to the supplier right from the system.

Purchase order management in 4castplus software

Inventory planning and optimization

Estimating the optimal amount of inventory that has to be purchased, whether as raw materials for manufacturing needs or goods for sale, is a challenging task. It has to match production/storage/sales capacity on one hand and volatile customer demand on the other.

Demand forecasting is obviously vital for wholesalers and retailers, but manufacturers need it as well since not all product lines are the same and the amounts to be produced have to be carefully planned according to anticipated demand. Recent research by Bain & Company found that 56 percent of supply chain companies plan to invest more in demand forecasting due to the impact of the COVID-10 pandemic.

Technology helps analyze historic and current trends and come up with recommendations on optimal stock amounts based on customer behavior predictions. In this way, you increase turnover and avoid both understocking (leading to customer dissatisfaction) and overstocking (leading to extra holding expenses and unsold leftovers).

Read more about demand forecasting in our dedicated article or watch a short video about how it works.

How to predict customer demand?

Inventory optimization analyzes the popularity of products and facilitates ordering not only the right amounts, but also the right items. It also involves optimizing the use of the storage space. There are a number of techniques different businesses implement in an effort to optimize their inventory.

- ABC analysis classifies all items into 3 groups according to their popularity (A being the most popular and C being the least). It uses the 80/20 Pareto rule and determines what products bring you the most profit and require special attention.

ABC inventory management, source: Brightpearl

- The just-in-time (JIT) approach involves holding as little stock as possible. Basically, that’s how McDonald’s works -- they start assembling burgers only after the order is taken. In this way, storage costs are minimized, but the risks of stockouts and non-fulfillments are much higher.

- Dropshipping and cross-docking can also be considered inventory management techniques since their implementation basically eliminates the need for storage. However, they require accurate organization of all operations and high agility in reacting to disruptions. Check our articles about cross-docking and yard management for some insights on how to optimize such activities.

- Backordering means purchasing inventory only after it’s sold or ordered from you. It lowers holding costs and risks of overstocking but can be challenging to do with multiple items and may result in customer dissatisfaction caused by longer time to fulfillment.

- Safety stock is a certain reserve, typically of fast-moving products, that is kept as a buffer in case of unexpected demand fluctuations or supply disruptions. Having it can protect from stockout but requires extra expenses for storage and ties up your capital. Nevertheless, study shows that almost 20 percent of companies plan to keep more inventory after the COVID-19 supply disruptions.

- FIFO vs LIFO stand for first in, first out vs last in, first out and are the two main approaches to moving inventory. FIFO is more common as it gets rid of older items first and prevents expiry and spoilage.

- Consignment is giving goods to a consignee (usually a retailer) for sale, without receiving payment upfront but holding ownership until the final sale takes place and the money is received.

Back in the late 1990s, when Walmart and Kmart were in fierce battle, Walmart implemented JIT to restock more efficiently. Within a few years, Walmart’s stock prices grew 82 percent, and Kmart’s fell 63 percent (and it soon filed for bankruptcy), proving the effectiveness of inventory optimization.

Properly fine-tuned, IMSs automate inventory optimization activities, make necessary calculations and analysis, and provide recommendations on what items are in higher demand, what quantities have to be reordered and when, etc. All of which will allow you to make decisions on further reordering and marketing activities (like promoting slow-moving items and offering discounts).

Customer and supplier management

Managing your suppliers involves analyzing their performance to ensure the uninterrupted and reliable delivery of goods. IMSs can help you track the status of your orders, shipment errors, and lead times across suppliers so that you can keep reordering under control.

Having a customer database is important not only to automate the document filling process, but also for analytical purposes. Studying purchase patterns is a basis for demand forecasting, while analyzing customer behavior lets you adjust your marketing strategy, improve service, and increase personalization.

Besides, the aforementioned Pareto principle is applicable here as well, i.e., 20 percent of customers bring you 80 percent of profit so knowing who your Most Important Customers are enables you to give them special attention.

Production management

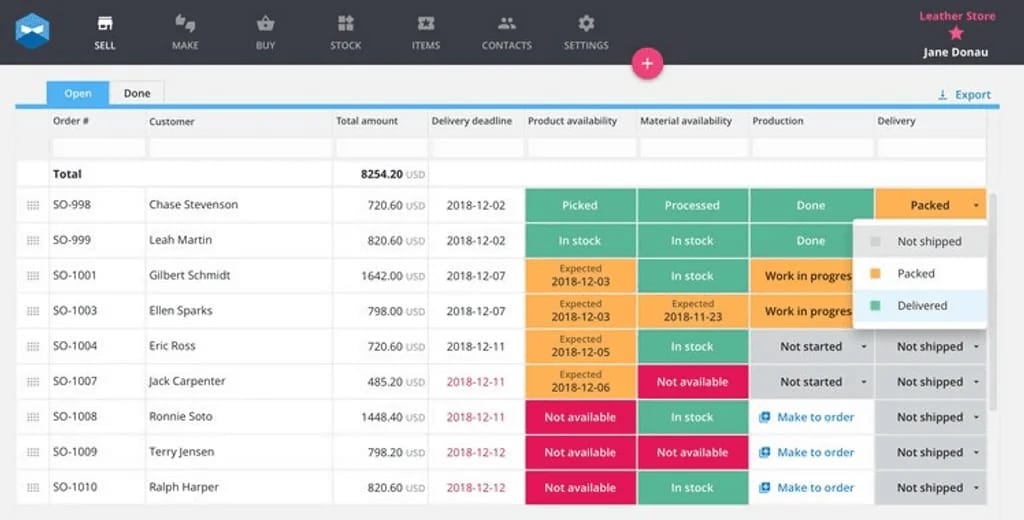

The IMS manufacturing module, in addition to general inventory control and reordering functionality, can also support your production process in a number of ways.

- The complex, multi-layered bills of materials can be created and managed together with subassemblies.

- You have shop floor management optimized as manufacturing orders, work orders, purchase orders, and sales orders are connected in a single workflow.

- You can estimate the final cost of a product, considering the cost of materials involved as well as other expenses such as labor, electricity, etc.

Inventory management for manufacturing, source: Katana

Sales management

Sales management functionality is probably more important to retail and eCommerce businesses than to manufacturers. For example, supporting multichannel sales lets you synchronize your shipments and automatically update stock levels after items are sold across multiple channels (in-store, through your website, through online marketplaces, etc.).

Another useful feature is product bundling. If you offer a mix and match option to let your customers create a preferred combination of products, the IMS has to define availability of each element and update inventory levels after the kit is sold.

If you practice backordering or you have reliable suppliers with strict lead times, make sure your IMS has override options. That way, you’ll be able to keep selling even if the system shows you're out of stock.

Reporting and analytics

If you want to improve something, you first have to know exactly how it works. Monitoring performance is crucial for getting a full picture of your business and understanding what areas need optimization. Collecting and analyzing data across different modules and departments lets you identify your weaknesses and adjust your strategy accordingly.

The IMS can help you create multiple inventory-related reports, e.g., incoming stock reports, location reports, inventory value reports, etc. You can see your order and shipment status, monitor your suppliers, track production efficiency metrics, generate sales summaries, and much more.

Read about the most widely used inventory management KPIs in a separate post.

Visualizing your transaction history enables you to identify purchase and sales trends. Besides, the IMS software can also help you analyze the performance of your sales channels and your customer behavior to make informed marketing decisions.

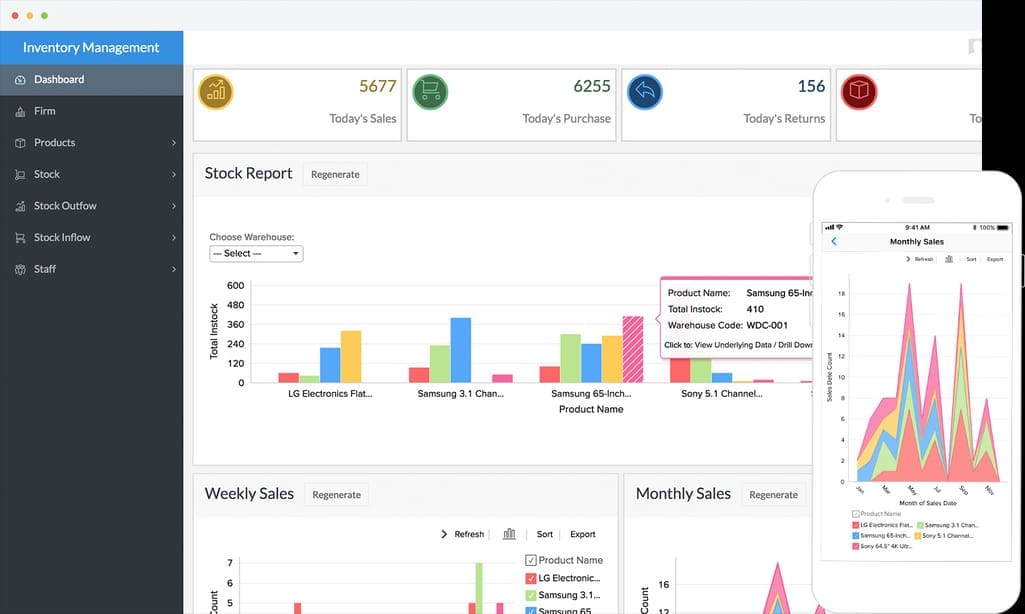

Inventory management dashboard, source: Zoho

In addition to the aforementioned modules, inventory management software digitizes documentation and procedures, facilitating communication between employees and improving collaboration across departments. You can also set up different user roles to ensure that your staff has access to necessary information and can easily share and exchange data. In the next section, we’ll explain what system connections can be created to support such interactions.

Possible integrations of inventory management systems

Inventory management is probably not your only business function and you most likely have other pieces of software in use. To ensure seamless data exchange, you should establish integrations between the systems.

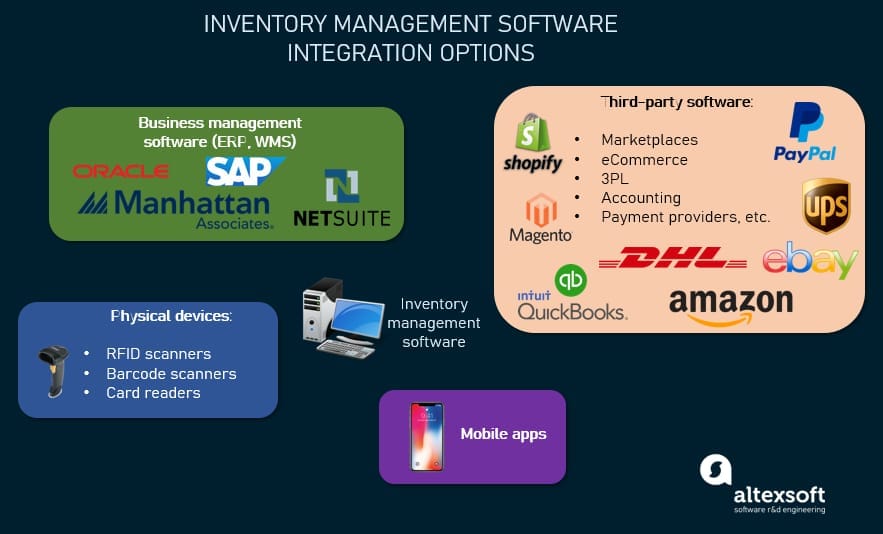

Possible IMS integrations

- If you already have business management software such as a WMS or ERP and you decide to add a separate IMS, integration is a must to create an effortless two-way data flow.

- If you add an IMS to a focused software that you are using for specific purposes, connecting them is also necessary to enable data sharing. Examples of such software are eCommerce platforms, POS systems, marketplaces, inventory planners, retail platforms, CRM systems, dropshipping platforms, 3PL systems, channel managers, BI tools, accounting systems, payment providers, etc.

- Besides software, you can also integrate your IMS with such physical devices as barcode scanners, RFID scanners, credit card readers, etc., to automate your stock tracking and transaction processing operations.

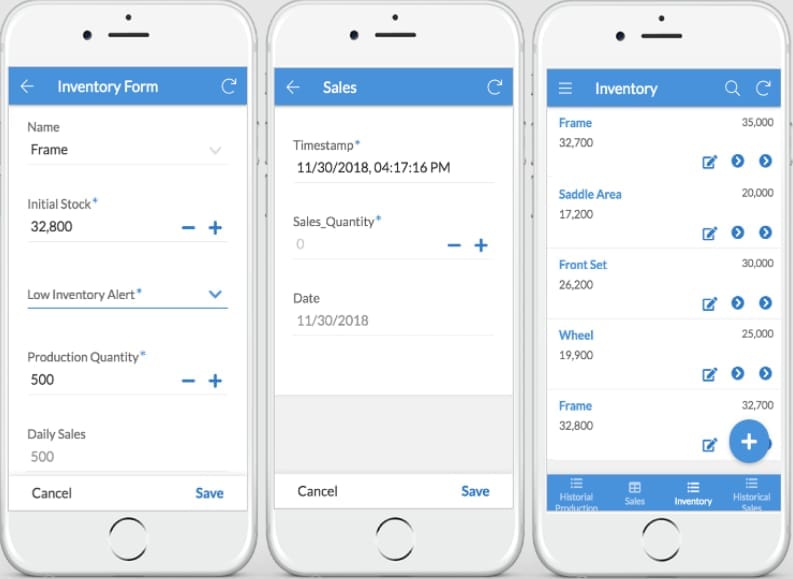

- Having a connected mobile app comes in handy as it allows you to keep your business under control from anywhere at any time. It can also help with communication between employees, support sales and warehouse operations with real-time inventory information, or act as a scanner instead of a separate device.

Inventory management mobile app, source: AppSheet

Main providers of inventory management systems

As we’ve already mentioned, there are plenty of standalone IMS solutions out there. Here we’ll just briefly list some of the most popular ones to show you the options.

Cin7 is more of an ERP than an inventory management platform as it’s packed with features to automate your daily operations. It’s designed to connect your warehouse, orders, sales channels, reporting, and more, offering solutions for businesses of any size and for various industries.

QuickBooks Commerce (formerly TradeGecko) is a comprehensive platform that would work for any supply chain business as it supports warehousing, manufacturing, and all aspects of inventory management. It also has a sales app and a wide variety of integrations.

Zoho Inventory is a part of the Zoho family of instruments for managing all business aspects. It has a lot of advanced features (such as multichannel selling, multi-warehouse management, item kitting, backorders, dropshipping, etc.), many integration options, even some useful free tools. However, it doesn’t support demand forecasting and it has some limitations on the number of users and warehouses, so it's an excellent solution for smaller businesses.

Fishbowl Inventory has 2 main modules: Fishbowl Warehouse and Fishbowl Manufacturing, with advanced features and numerous integration options. This one's for you if you need to effectively manage these aspects. But, if you work in the retail or eCommerce sector, it has more limited functionality compared to other tools. Also note that it has multiple mobile and hardware products, but you have to pay extra for every add-on.

Lightspeed is actually a POS system provider for retail and eCommerce stores, but the reviews and ratings are so great that we included it in our list. It has multiple modules with robust inventory management functionality that is connected to sales, CRM, analytics, and more.

Final recommendations and implementation options

As with any other technology, there are several approaches to implementation, depending on your specific business needs. We can’t describe all the possible scenarios as every company is different, but here are some typical ones.

For example, a small or medium-sized retail or eCommerce store might benefit most from off-the-shelf IMSs with basic inventory control, sales management, and reporting features. It’s a comparatively easy way to go, just note that the level of customization might not be enough to fit your unique business requirements perfectly.

Managing a warehouse or a wholesale company might require a comprehensive, full-fledged WMS or ERP platform that will cover multiple business aspects -- including inventory management. The advantage here is that the information will be easily shared between the modules as they comprise one single system. However, such software is even less likely to be tailored to your needs than the previous one.

If you run a factory or any production business, you might want to go either with a standalone IMS solution with a strong manufacturing module or choose a set of separate tools focused on managing a specific process (such as BOM tools or inventory planners). It’s cheaper than acquiring a multi-featured platform, but you’ll have to integrate it with your other software to ensure seamless data exchange.

In case you manage an enterprise-scale business that includes multiple facilities, the best option for you would probably be creating your own custom software. Developed with the unique specifics of your business in mind, it would be fine tuned to your operational needs. This way, you get maximum flexibility and boost your performance as you target concrete business aspects to get the best result.

Maria is a curious researcher, passionate about discovering how technologies change the world. She started her career in logistics but has dedicated the last five years to exploring travel tech, large travel businesses, and product management best practices.

Want to write an article for our blog? Read our requirements and guidelines to become a contributor.