Managing a supply chain involves organizing and controlling numerous processes. Supply chain practitioners and CEOs surveyed by 6 River share that the main challenges of the industry are

- keeping up with rapidly changing customer demand,

- dealing with delays and disruptions,

- inefficient planning,

- lack of automation,

- rising costs (of transportation, labor, etc.),

- diversity of sales channels, and

- complex structure resulting in siloed data and lack of visibility.

These challenges can be addressed by intelligent management supported by data analytics and business intelligence (BI) that allow for getting insights from available data and making data-informed decisions to support company development.

So, in this article, we’d like to elaborate on how analytics and BI software can benefit all aspects of supply chain management.

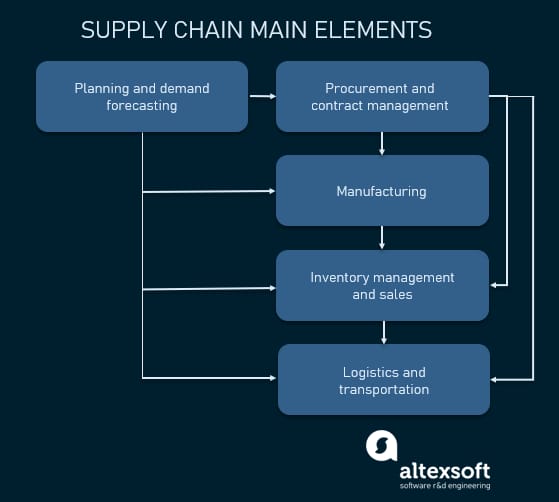

Supply chain management process

Before we talk about the opportunities that analytics provides, let’s briefly describe the process of managing a supply chain. It includes a broad range of tightly interrelated activities that we can categorize in several major groups.

Supply chain management process

- Planning mostly concerns demand forecasting and resource planning.

- Procurement is a set of operations related to choosing vendors, negotiating the terms of cooperation, and buying supplies needed for your business.

- Manufacturing deals with production and capacity management.

- Inventory management is focused on keeping the optimal stock balance, sales, and warehousing operations.

- Logistics management covers order fulfillment and all delivery activities.

Each element requires making numerous strategic and tactical decisions daily. Analytics brings visibility into operations, helps find dependencies and hidden patterns, and can predict possible outcomes. All this supports decision-making and makes it proactive rather than reactive, allowing for seizing opportunities and avoiding risks.

Now, let’s find out what specific optimization possibilities analytics can provide in each supply chain element.

Optimization opportunities offered by analytics

Analytics in planning and demand forecasting

The research by BI-Survey disclosed that the main goal of 57 percent of companies that invest in BI is enhancing their sales planning and forecasting to gain a competitive advantage.

Everything starts with a plan. And planning, in turn, relies on understanding of current performance, past trends, existing risks, and possible future scenarios. To support the planning process, predictive analytics and machine learning (ML) techniques can be implemented.

For a supply chain company, predicting customer demand is vital since it influences all the other elements and becomes the basis for planning procurement, production capacities, logistics, sales, and so on.

In 2013, Amazon were granted a patent for their so-called anticipatory shipping approach. It’s a method of using powerful predictive analytics techniques to send products to customers even before they are ordered. Imagine, how much they know about you and your preferences to -- as wild as it may sound -- make it actually work. Well, we’ll have a chance to check it soon.

Forecasting customer demand is estimating who will buy your product or service, for what price, where, and in what quantities. We have previously described demand forecasting methods and the role of machine learning solutions in a dedicated article. Here’s also a video for an overview of demand forecasting and predictive analytics.

Demand forecasting explained

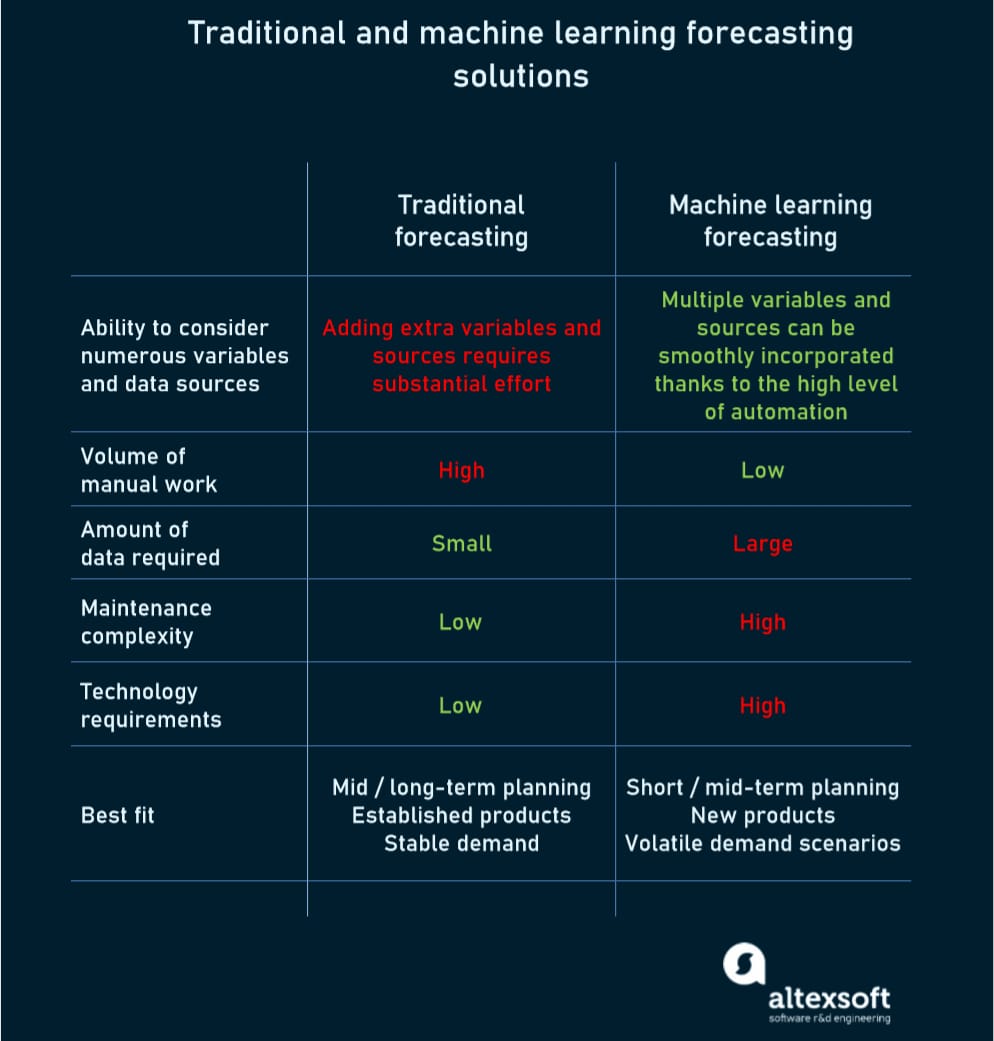

There are two main approaches to demand planning:

Traditional statistical methods make forecasts based on historical data and assume the continuation of existing trends. The accuracy of such forecasts is unreliable since it implies general stability that is rare for the extremely changing environment of most markets. Today, consumers’ preferences change moment to moment and often chaotically. A single comment in social media can have a tremendous impact, so traditional methods are not always effective.

Machine learning techniques analyze big data from various sources, identify hidden patterns and unobvious relationships between variables, and create complex models that can be retrained to automatically adapt to changing conditions. This approach demands significant investments in software, equipment, and human resources to create advanced data architecture, but the resulting accuracy and visibility are worth the price.

Comparison between traditional and machine learning approaches to demand forecasting

Resource planning is closely related to demand forecasting as the volumes of procurement should match the planned production level.

Besides planning, conducting deep research of customer tastes and preferences as well as sales trends would help you reduce returns and expenses on reverse logistics. Managing distribution also relies on market research as choosing the right distribution channels is vital for optimal customer reach.

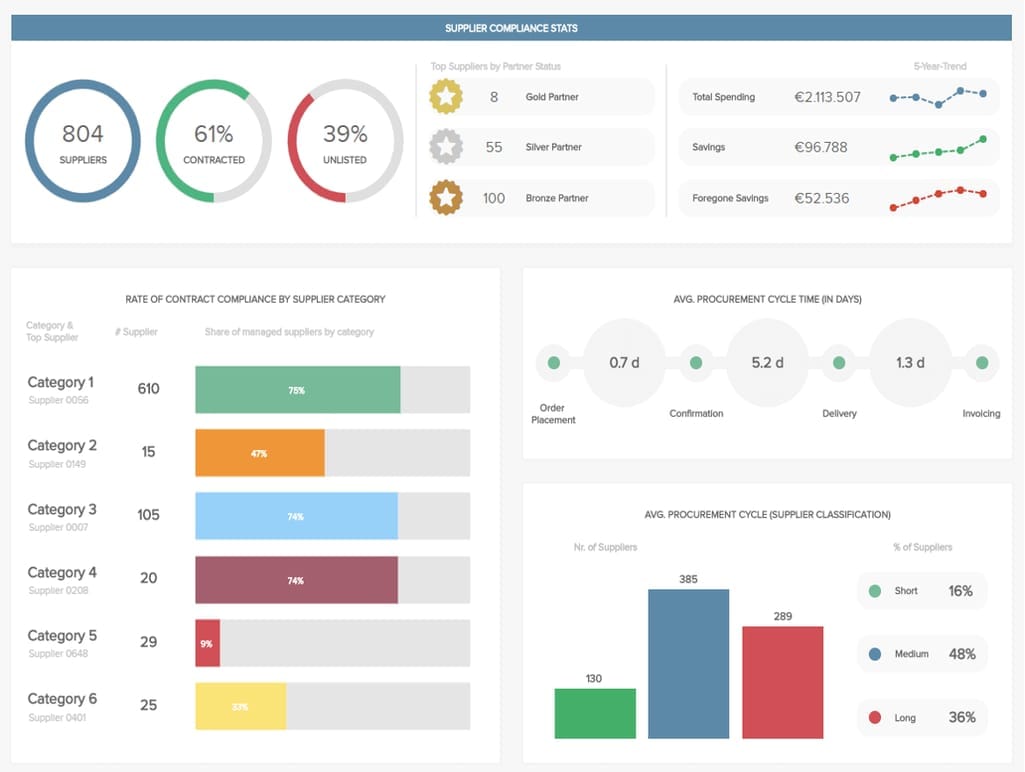

Analytics in procurement and contract management

We’ve already mentioned that analytics can help with planning the amount of resources needed -- depending on the volume of production planned. Now that you know how much you need to buy, you have to determine where or from whom to buy.

Supplier evaluation is important if you want to make sure your future partner is trustworthy and reliable. The data that your procurement management software generates can help you analyze potential suppliers’ performance by comparing their KPIs, prices, compliance, and other variables.

Supplier performance review implies analyzing current suppliers’ metrics throughout your partnership to help you with future negotiations and strategies. It’s important to monitor your vendors’ accountability (i.e., defect rate), customer service (i.e., time needed for resolving issues), and possible additional charges. Evaluating timeliness of delivery and quality of delivered products, you can weed out the poor-performing vendors. Besides, advanced analytics techniques allow for predicting possible supply disruptions (such as bankruptcy or delivery delays) so that you can take preventive measures.

Example of the procurement dashboard interface

Read more about analytics in procurement in our dedicated post.

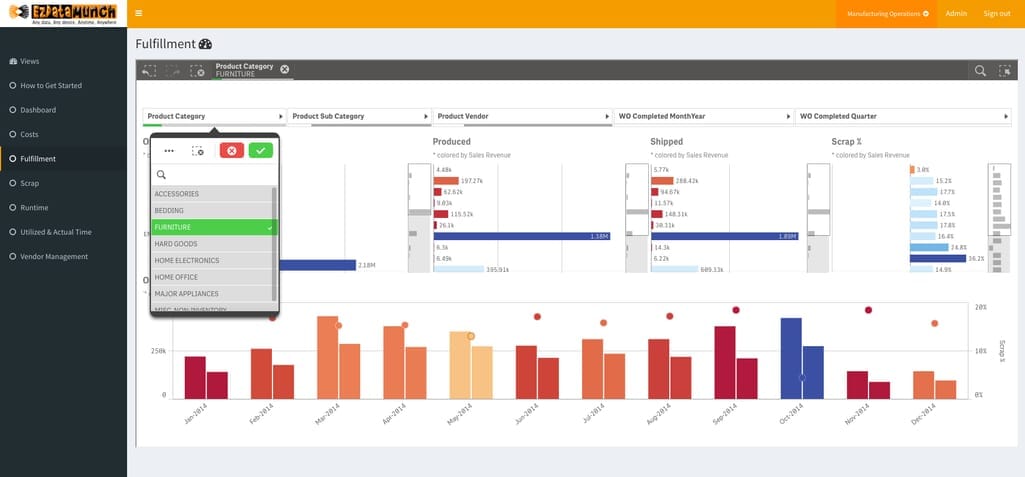

Analytics in manufacturing

Manufacturing has intense dependency on accurate planning, but at the same time must be flexible to adapt to possible demand changes. Another challenge is the never-ending need for optimization and maximizing performance. How to reduce production time and cost? How to increase quality? How to use manpower and equipment more efficiently? These are some of the questions that can be answered with the help of analyzing production-related information.

Monitoring production performance. Manufacturing is typically characterized by producing a lot of various disparate data that is hard to organize and analyze, especially with the spread of Internet of Things (IoT) devices. Analytics and BI tools can consolidate and visualize all the important information that would permit you monitor your production process more efficiently. Here are some crucial production aspects that you can look deeper into with the help of analytics software:

- machine/cell performance,

- shift performance,

- throughput,

- quality and scrap rates, etc.

Production performance dashboard example

Optimizing maintenance. Data mining techniques can help you to find dependencies between seemingly disconnected factors. For example, you can see that the machine breakdown increased, and the root cause analysis shows that it happened because of using cheaper spare parts or fuel. More advanced analytics enable conducting preventive or predictive maintenance based on data from IoT devices and various sensors connected to equipment.

Cost control. Cost analysis methods such as BOM (bills of material) analysis would bring understanding of the cost structure of your products and unveil opportunities for reducing your expenses. Applying cost-benefit analysis, you can measure the benefits of decisions taken, while marginal analysis will let you determine the optimal production capacity.

Quality management. Analyzing both quantitative and qualitative data from manufacturing operations and customer feedback (coming from customer support, social media, warranty claims, and marketing research), you can obtain insights on how to improve the quality and design of your product to match customer expectations. Besides, you can discover reasons behind product defects, even if they happen years later.

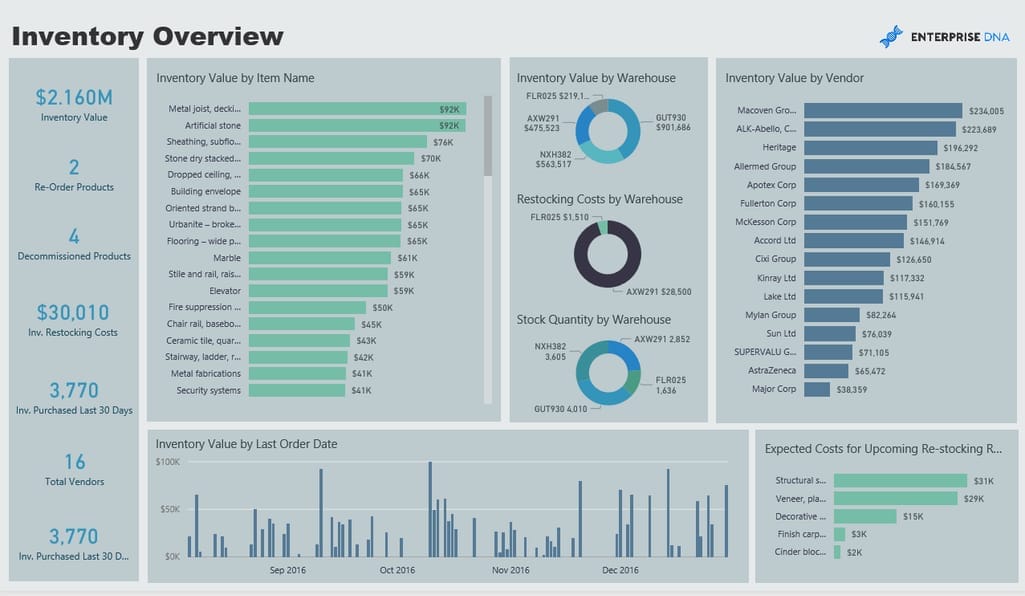

Analytics in inventory management and sales

Inventory management deals with handling stock of all types, i.e., raw materials, finished/for-sale goods, MRO (maintenance, repair, and operations) goods, etc. Now, the main issue here is to have just the right quantity of needed items in the right location at the right time.

Stock management. Inventory levels are forecasted with the help of demand management we discussed above. Then, real-time analytics joins the game, tracking sales trends and inventory left, making suggestions on replenishments, identifying best-selling items and those with worst performance (a so-called ABC analysis), and so on. That allows for avoiding both costly overstocking and frustrating stockouts (statistics claims that retail businesses lose $984 billion a year due to being out-of-stock). Moreover, you can find out why a product isn’t selling, i.e., because there’s no demand or it’s not promoted enough.

Optimizing warehousing operations. Analytics software can analyze the flow of goods to make recommendations on the optimal allocation of products and the most efficient routes to pick them.

Evaluating channel performance. Analytics and BI tools can create various reports to visualize the performance of your vendors, products, sales channels, etc., and help enhance inventory control and support further decision-making. For example, you can identify which channels can handle more stock or find out that some channels bring losses because logistics costs are higher than resulting profits.

Inventory management dashboard example

Shelf planning is another inventory-related activity that analytics techniques can help with. Considering historical and seasonal trends and analyzing current customer behavior would allow for optimizing product allocation as well as supply quantities. Besides, results of such analysis help adjust marketing strategies to get rid of slow-selling inventory (check our article on using ML in next best action marketing) and make targeted offers.

Pricing optimization is a process of adjusting your prices in consideration of various internal and external factors, i.e., market conditions, competitor actions, input costs, customer segmentation, etc. Monitoring sales data together with these variables would let you choose the optimal pricing strategy and maximize revenue. Here’s some great material worth checking out about ML in dynamic pricing and pricing optimization.

Reducing shrinkage becomes possible when all the internal and external data is combined in one system to be thoroughly analyzed. Predictive analytics helps discover and prevent losses caused by theft, shoplifting, poor management, and other unapparent reasons.

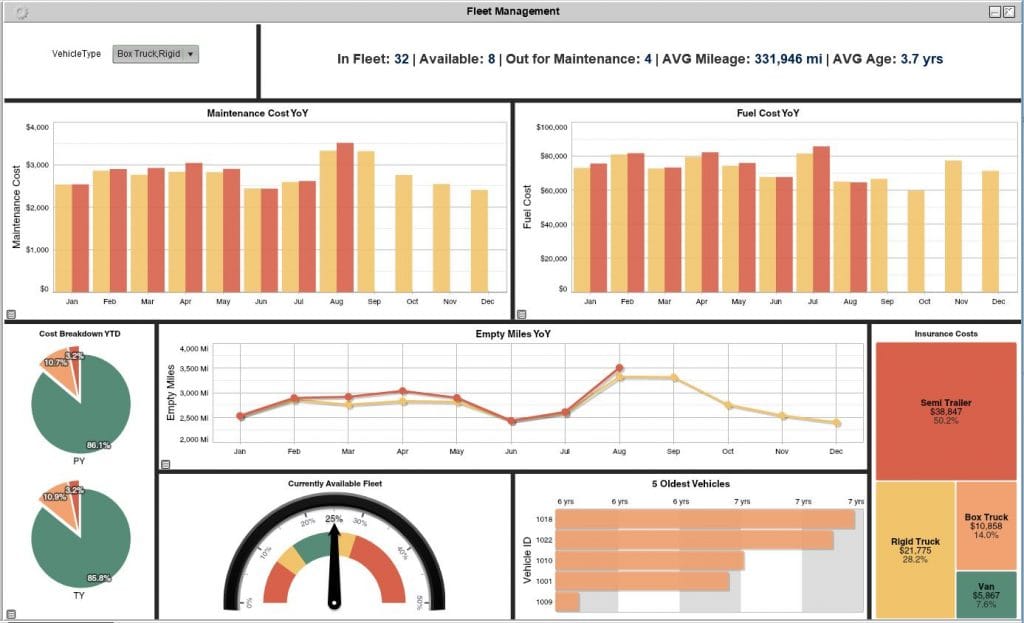

Analytics in logistics and transportation

There are numerous benefits that software in general (check logistics management system and transportation management system) and particularly analytics tools can provide to optimize logistics and transportation management.

Fleet management analytics dashboard

Fuel management. Analyzing driver behavior obtained from telematics devices can help reduce fuel costs (which can be a significant saving with fuel taking about one-fourth of total operational expenses).

Route optimization. Using weather and traffic information lets create more fuel-and-cost-efficient routes (the famous UPS route optimizer ORION helps save about 100 million miles and 10 million gallons of fuel per year -- pretty impressive, right?).

Shipment tracking and vehicle maintenance. Collecting data from sensors, cameras, and other IoT devices enables freight monitoring (so that you and your customers can always know the location and condition of the freight) and helps conduct preventive/predictive maintenance (repairing something before it breaks reduces expenses and downtime).

Reducing delays. Analyzing reasons for delivery delays provided by carriers lets identify which ones have the biggest impact on delivery time and require improvement to minimize delays.

Choosing carriers. If your company doesn’t operate its own fleet, but relies on 3PL companies to handle deliveries, analytics software can help with contract management we discussed above. It evaluates your potential and current partners to help select the most reliable ones and negotiate better conditions for cooperation.

Intermodal transport optimization. If your delivery specifics requires intermodal transportation, integrating major ports, carriers, and rail information would allow you to compare rates and create the most efficient route for every shipment.

Managing returns. Obviously, finding the reasons that drive returns would let you find ways to reduce their number. Maybe the product is not as described on your website, or your carriers mess up deliveries, or maybe there is some production defect -- whatever the issue is, it’s worth knowing.

Having discussed the multiple ways that data analytics and business intelligence can optimize supply chain operations, it’s time for some practical advice.

How to implement analytics and integrate it into the supply chain management process

Below are some actionable steps to start using your data and developing your company analytics with.

Identify your business problem

So, the first thing to do is to define your specific problems and objectives. Might sound easy, but it’s not always obvious when you start thinking deeper than “get more profit” and “reduce expenses”. Some sensible pain points you might think of can be:

- reducing inventory to release cash,

- finding more reliable suppliers,

- preventing equipment breakdown,

- increasing product quality, etc.

Understanding what problems have to be solved would define the direction of your further improvement.

Establish KPIs

Logically, the next step is specifying what criteria would let you track your progress and measure success. Obviously, you’re monitoring multiple metrics to get an understanding of your company’s performance, but KPIs are needed to show how you reach your specific business goals. For example, if you are concerned with the quality of your products, you can monitor scrap rate and number of returns. If you have issues with your suppliers, it’s worth paying attention to order accuracy, number/percentage of on-time deliveries, number/percentage of damaged products, etc.

Define data sources

Once you know the KPIs you want to focus on, you have to find data you will need for analysis. It’s important to understand which data and from which sources is already being used -- and which data is missing to accurately monitor your KPIs. You might find out that you’re lacking some important information or underusing some sources. In other cases, you might discover that you have the data, but it has to be prepared and digitized (like paper documents or qualitative data from emails or social media).

Data can be obtained from both inside your organization across different departments and outside it. Internal data sources include:

- an enterprise resource planning (ERP) system,

- a customer relationship management system,

- a logistics management system,

- a transportation management system,

- a warehouse management system,

- accounting software,

- IoT devices,

- eCommerce platforms,

- customer support,

- non-digital information like phone calls or printed documents, and so on.

External data sources include:

- B2B integration platforms,

- social media,

- partners’/competitors’ performance information,

- outside research,

- customer feedback, etc.

Assemble the data team

Depending on the complexity of your data architecture, consider hiring a business analyst, data engineer, or a team of data scientists to manage your company’s data in the most efficient way. An analyst would assess your business processes, work with data sets from various sources, and create data-based recommendations on improving products, services, processes, etc. Data engineers work with technologies, setting up and managing data pipelines to extract, store, and transform data for further usage. Data scientists implement ML and data mining techniques to create models, enable predictive analytics, and solve business problems.

Work on the culture

Creating a data-driven culture implies encouraging data sharing and data-based decision-making on all levels throughout the organization. Such initiatives have to be started from the top and supported by the management team to teach others and show benefits to other employees. Everybody in the company has to understand how analytics tools work, what value they bring, and how analytics data is related to KPIs. It’s also important to provide access to data, flatten the structure, and empower employees to make operational decisions. All that would facilitate and accelerate decision-making and encourage using analytics data.

Start with existing analytics capabilities

You can start off by using the reporting and analytics capabilities of your existing ERP or other business management system. Typically, such solutions include some analytics functionality, but it’s usually quite limited as your different systems are most probably not integrated with each other and you can't combine data from multiple sources to get custom reporting (that said, even basic analytics is better than none).

Develop business-specific analytics platform

Create a customized data architecture solution that will meet all the unique needs of your supply chain business and provide exactly the functions you need. You can use one of the BI platforms for the user’s interface, but you will still need some data engineering efforts to set up the data pipeline and streamline the flow of data from your data sources to the chosen interface.

Think about the functionality you want and results you’re looking for. If you only need to visualize and monitor your supply chain performance through the main KPIs, the standard reporting capabilities of your business management system would be enough. However, if you want to get granular actionable insights from available data, create accurate forecasts, and make data-driven decisions that lead to growth, it’s worth building a full-fledged data architecture that would support your business development.

A few more tips to consider

Here are some other thoughts on how to get the most out of your analytics software:

- Real-time analytics is the key to supply chain resilience. Collecting historical data and generating reports is also important, i.e., for observing trends or monitoring performance, but using real-time data would let you immediately know about malfunctions, accidents, or any sudden changes so that you can take rapid action and avoid losses. Customized alerts and notifications help quickly obtain targeted information about disruptions.

- Implementing self-service BI would enable sharing data across the organization and provide access to multiple users outside the CEO-suite. That, in turn, would drive business agility and accelerate decision-making on all levels.

- Deriving from the previous one, it’s important to ensure that dashboards and reports are tailored to different user roles. That means setting different access preferences for users of different levels and also ensuring a user-friendly interface for non-technical employees.

- Mobility, or the ability to use BI tools and see data analysis results on mobile devices, is another factor that expedites the decision-making processes.

- Seamless integrations are key to smooth data sharing across departments and software modules. Having all the company data in one system is the only way to conduct accurate analysis. So, you have to ensure that all the data sources such as business management systems, web store platforms, IoT devices, 3PL or carrier systems, etc., are connected and synchronized with your BI software. Sometimes, BI platforms offer some of these integrations out of the box, but it’s worth considering partnering with an integration provider to set up a perfect customized integration architecture.

- Deployment type is another significant decision to make. Typically, on-premise software is thought of as more secure, reliable, and customizable, while cloud-based is cheaper and more scalable. But now online solutions have developed to such an extent that they can easily compete with traditional on-premise platforms.

- Sometimes, the final cost of a software is not obvious and, besides a subscription and/or monthly fee, can include hidden expenses such as additional customization, after-purchase support, hardware costs, implementation and training costs, etc. Be sure to take everything into account.

Only with such a holistic approach to data, can you build a prosperous business. Analytics and BI software can provide you with information that you can transform into actions to improve your supply chain efficiency, ensure customer satisfaction, reduce expenses, and achieve your business goals.